The new generation corner Europanels flashing with concealed fixings have been developed primarily for aesthetic finishing corners of buildings made of sandwich panels mounted horizontally.

3.1. Auxiliary brackets (base) 047

|

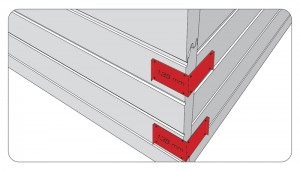

After attaching sandwich panels to the structure, corner flashing installation starts from arrangement, leveling and screwing auxiliary brackets 047 to the panel cladding. They have one fixed dimension (135mm) and the second is variable, depending on the thickness of the wall panels used at the facility. If the panels come to the front in the corner (are not cut at an angle of 45), the fixed-dimension side should be at the panel without the joint, and the second (variable) should go beyond the panels’ joint. Per 1 piece of outer finishing 046 with the length of 2.5 m, 4 pieces of brackets 047 should be used. Distance between the brackets: one on each end of the finishing, and the other two at a distance of 1 m from each other. In the case of end brackets, they are to be visible after embedding flashings. Only the starting flashing should face the bracket at the bottom (as the end on from the top) . Auxiliary brackets are mounted to the cladding with self-tapping screws or farmers. Per one bracket, four jigs placed in the corners are used, at a distance of about 25mm from the edge of the bracket. |

3.2. Corner angle assembly 046

|

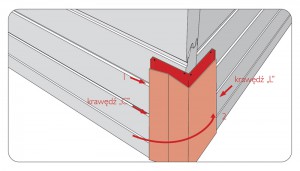

After such preparation of mounting brackets, you can install the outer angle 046. One flashing edge (profiled) is bent into the shape of the letter “C”, the second (variable, non-profiled) in the shape of the letter “L”. First, place the “C” edge into the gap between the cladding and the sandwich panel auxiliary bracket (step 1), then adjust the flashing in such a way as to keep 1mm space between the edge of the flashing and the panel flashings at the other side (step 2). During flashing assembly, pay attention to the sharp “L” edge. Be careful to avoid any body cuts and scratches on the sandwich panel cladding. |

3.3. Final assembly

|

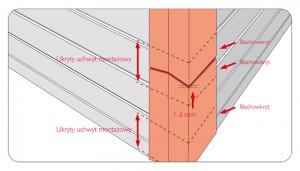

Flashings of this type are not intended for overlapping connection alongside the panel. For this reason, they are symmetric, and at the place of the connection, a gap with the width of about 2mm must be maintained. Flashing 046 is mounted on the “L” side with mini self-tapping screws or sealed steel rivets to the profiled element of bracket 047 at four locations, i.e. one self-tapping screw on each auxiliary bracket of the given flashing. During installation, pay attention not to scratch the cladding of the sandwich panel during drilling / screwing. |