PolTherma CS and PolTherma TS – Panels assembly with PU foam

TECHNICAL INFORMATION ABOUT THE METHOD OF FOAM APPLICATION ON THE JOINT OF THE PolTherma TS and CS PANEL

In case of PolTherma TS and CS series which are to be assembled in the vertical systemm it is advisable to specially prepare panel joints for foam application.

For the preparation of the joint surface you need:

- a sponge;

- water;

- water sprayer – pressure sprayer;

- low-pressure, polyurethane foam with closed core,

- a foam gun (for better control of the application, no hose foams are recommended).

Before assembly make sure that the foam containers used for the application have the appropriate temperature (not lower than room temperature). Do not apply frosted foam!

1.

|

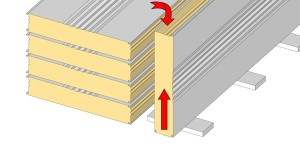

Take the panel from the batch, put the longer side on a surface protected with styrofoam spacer. The panel tongue(steel lock element) is to be facing upward. |

2.

3.

|

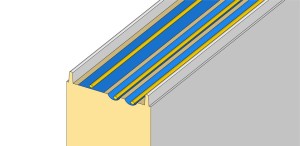

Apply 3-4 foam applications of small diameter (max 10mm each): one in the joint hollows and one or two (TS and CS200) on the flat part. Do not apply too much foam! |

4.

|

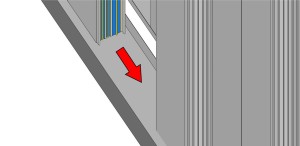

With the spraying machine, lightly moisten the surface of the applied foam with water and allow the surface to harden, i.e. to create so called peel which does not adhere in contact. |  |

|

5.

|

Place the panel on the structure, press and fasten with the connectors. Repeat steps 1-5. |

PDF guide file to download here.

For any possible inquiries / consultations, please call 608 064 085 or e-mail: kk@europanels.pl

English

English